Description

Motone Cylinder Stud Knuckles Caps MMU085 – Precision CNC-Machined Engine Detailing

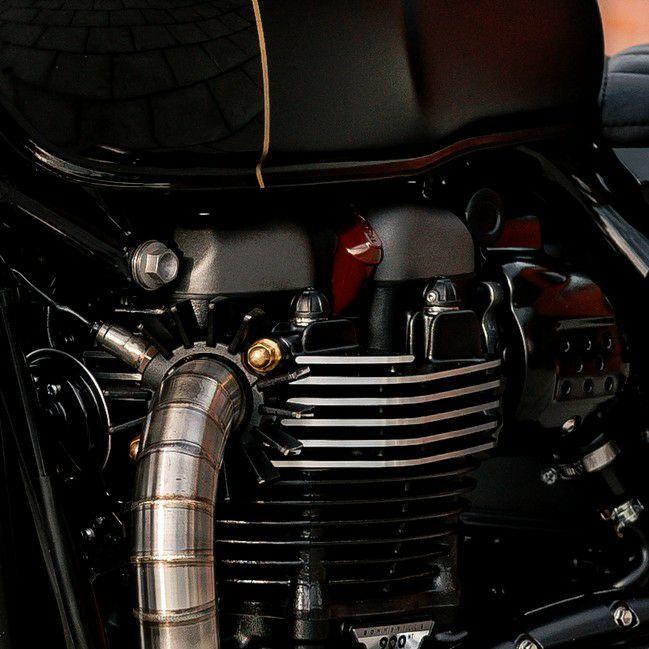

Replace exposed cylinder head stud threads with refined detailing. The Motone Cylinder Stud Knuckles Caps MMU085 transform utilitarian fasteners into styled accent pieces, featuring CNC-machined billet aluminum with durable black anodizing for clean, finished engine bay presentation.

Key Features

- Billet Aluminum Construction → CNC-machined from solid aluminum bar stock for precise dimensions and lightweight strength compared to die-cast alternatives

- Type II Hard Anodizing → Black anodized finish penetrates aluminum surface for superior wear resistance and corrosion protection that won’t chip or flake

- Knuckle Dome Profile → Low-profile rounded cap design maintains ground clearance while covering exposed stud threads elegantly

- Complete 8-Piece Set → Includes all caps needed to cover both cylinder head studs (4 caps per cylinder)

- Thread-In Installation → Self-tapping threads create secure engagement without requiring permanent adhesives or complex mounting hardware

Technical Specifications

| Specification | Details |

|---|---|

| Part Number | MMU085 |

| Material | CNC-Machined Billet Aluminum |

| Finish | Type II Hard Anodized Black |

| Profile | Knuckle Dome (Low-Profile) |

| Set Contents | 8 Caps (4 per Cylinder) |

| Thread Type | Self-Tapping Aluminum Thread |

| Installation | Thread-On (No Drilling) |

Compatible Triumph Models

- Bonneville T100 (2001-2025)

- Bonneville T120 (2016-2025)

- Street Twin (2016-2025)

- Street Scrambler (2017-2025)

- Thruxton 900/1200 (2004-2025)

- Bonneville Bobber (2017-2025)

- Speedmaster (2018-2025)

- Speed Twin (2019-2025)

- Scrambler 900/1200 (2006-2025)

Installation Guide

- Ensure engine is cool before starting installation to prevent burns and thermal expansion issues

- Clean cylinder head stud threads with a wire brush to remove road grime and oxidation

- Apply a small amount of anti-seize compound to the first 2-3 threads of each stud

- Thread each knuckle cap clockwise onto the exposed stud by hand until snug (do not use tools—hand-tight only)

- Ensure all 8 caps sit level and flush against the cylinder head cooling fins

- Torque is not required—aluminum threads grip sufficiently with hand pressure alone

Why Replace Exposed Studs?

Factory cylinder head studs protrude above the cooling fins with exposed threads that collect road debris, create visual clutter, and present a utilitarian appearance inconsistent with custom builds. These knuckle caps eliminate thread exposure while adding refined detailing that integrates seamlessly with polished or blacked-out engine configurations.

Maintenance

Clean caps during routine engine washes using mild soap and water. Avoid high-pressure washers aimed directly at caps, as excessive force may loosen thread engagement. Inspect caps every 3 months for tightness—vibration can gradually back out threaded components over time.

British Craftsmanship

Designed and manufactured by Motone Customs in the United Kingdom, these caps represent the same precision engineering standards that made British motorcycles legendary. Every component undergoes strict quality control to ensure perfect fit and long-term durability.